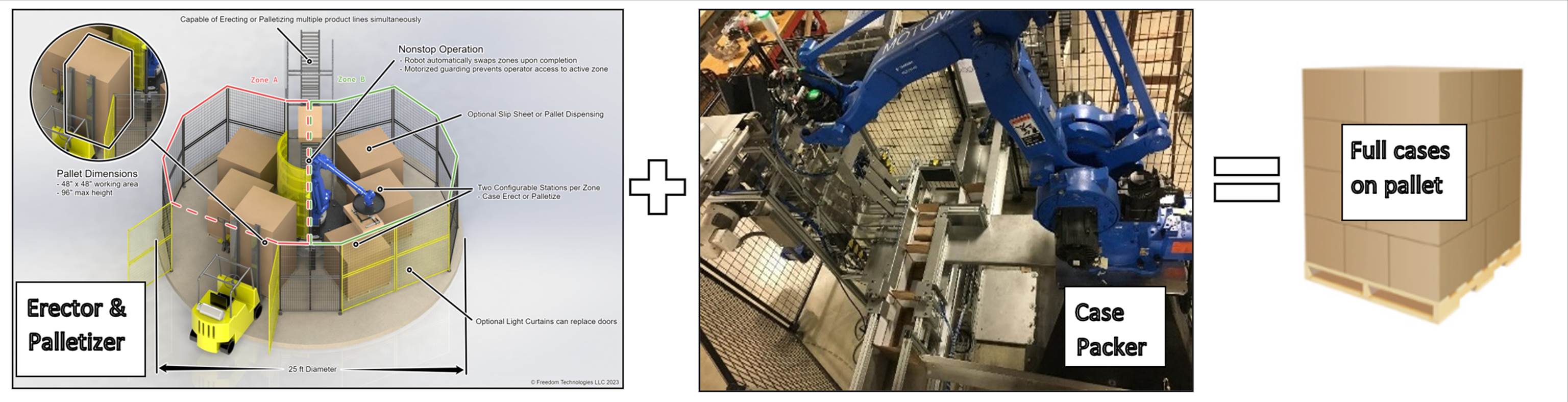

Case Erector Packer Palletizer:

Robot case erector, packer & palletizer all in one: (up to 9 cases per minute)

1. The

robot takes KDFs

(knocked down flat cases) right from the pallet erects the

case while stacking full cases on pallets.

2. Fast

case erection cycle allows for simultaneous palletizing.

3. The inevitable stuck together cases that normally jam a conventional case packer or erector are sensed and tossed aside eliminating production stoppages.

4. †Accumulation of both erected cases

and full cases provides valuable process buffers to maximize process speed.

5. Innovative

hard guarded split work cell provides safe operator access for skids to be

placed and removed in one half of the cell while the robot remains at 100%

speed in the other half.

6. Exclusive

3D vision system monitors all case erecting and loading stations every cycle

preventing crashes by allowing for safe high-speed operation.

7. Yaskawa Motoman robot control thru AOIís on a Rockwell CompactLogix platform with PanelView Plus human interface that allows easy integration to box loading equipment either supplied by us or others.

8. We

supply industry standard and custom case packers built to bridge the gap

between the erector and palletizer above.

9.

Flexible robot erector tool accommodates a wide range of

boxes with no manual adjustments.

11.

High-end system has automatic

pallet insertion and removal. It is supplied with pallet dispenser, AGVs

(automated guided vehicle), pallet wrapper, full pallet staging area and full

KDFs staging area.† This configuration is

intended to service more than 4 production lines.

Call us today

for a live demonstration on our floor.